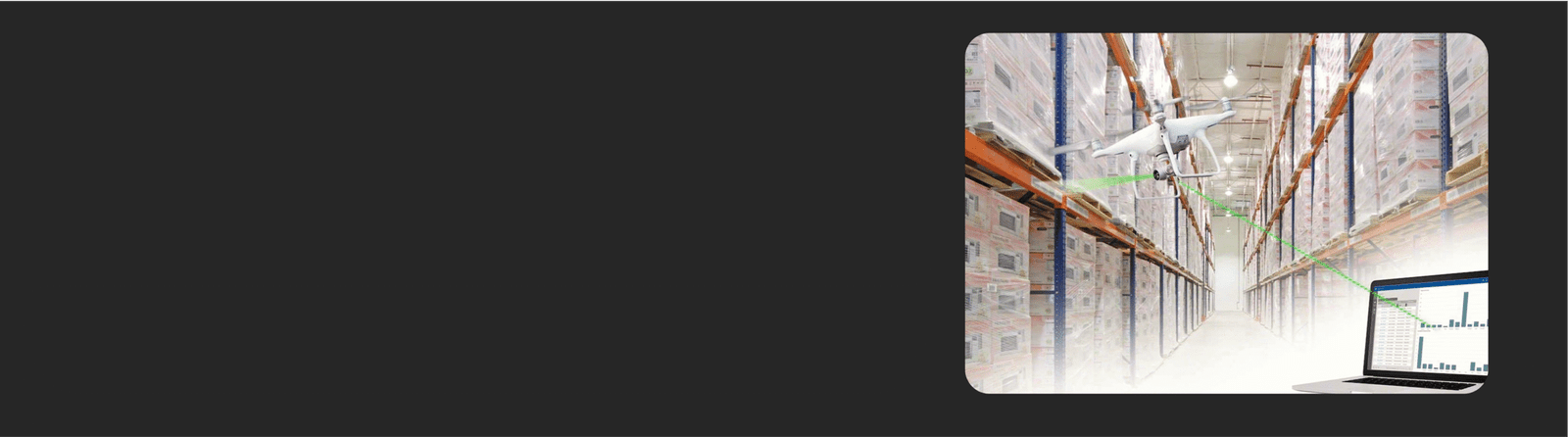

Redefine Warehouse Inventory with Autonomous Drone Technology

From shelves to systems—streamline warehouse audits with precision drones and reduced workforce dependency.

Smart Inventory from Sky-Level Precision

Our autonomous drones scan barcodes, rack labels, and inventory positions from floor to ceiling, 24/7, helping you cut costs, reduce manual errors, and optimize operations.

Scans 100–300 pallet locations/hour

Works in low light

and off-hours

Detects empty slots, misplaced goods, and label errors

Real-time data synced

to the dashboard

Where Can Warehouse Drones Be Deployed?

3PL / Logistics

Retail Warehousing

E-commerce Hubs

Cold Storage

Pharma / FMCG

Manufacturing Plants

How It Works?

Zero Human Intervention. Fully Autonomous.

Mission Control

Drone Fleet

Charging Station

Dashboard

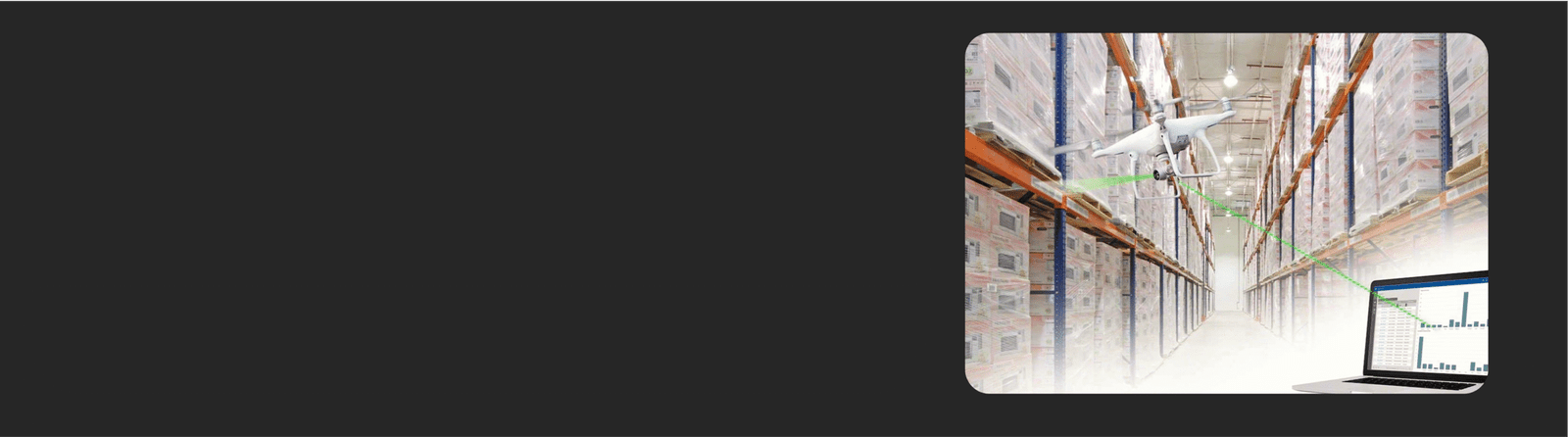

Night Scan for Moved or New Locations

Quickly detect misplaced or newly added items with automated nightly

drone scans, ensuring up-to-date inventory without manual checks.

Weekly Empty Slot Validation

Identify and validate vacant slots across shelves to optimize

storage utilization and reduce wasted space.

Monthly Full Warehouse Inventory

Perform a complete, accurate warehouse stock count without shutting down

operations or relying on large manpower teams.

Cycle Counting & Custom Spot Scans

Enable targeted cycle counts and on-demand spot checks for specific

SKUs, aisles, or zones to maintain continuous accuracy.

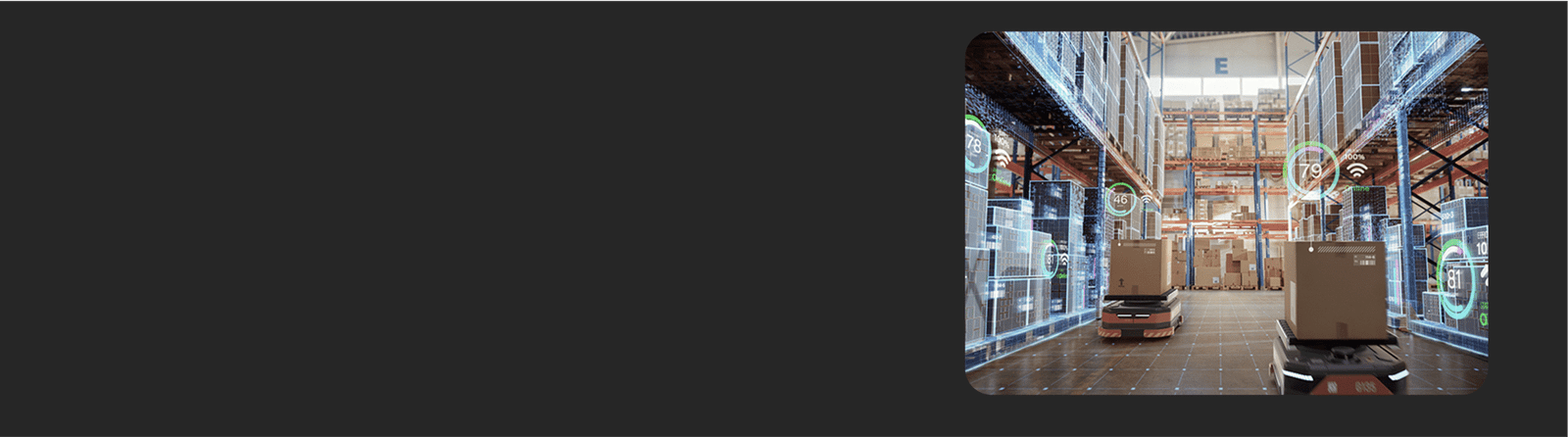

The Smarter Way to Count Inventory

Streamline your inventory process with smarter, faster, and more efficient solutions—saving time, cost, and resources at every step.

Reduces Theft & Discrepancies

Real-Time Inventory

Insights

No Need for Wi-Fi Infrastructure

Lower Energy Consumption

Cut Equipment Usage

Faster ROI

Let’s Make Your Warehouse Smarter

From site survey to live operations, our team handles the rollout with minimal disruption, while your warehouse continues to operate.

01

Discovery & Planning

We assess your warehouse layout, storage zones, inventory types, and scanning needs.

02

Workflow Mapping

Drone flight paths, scan checkpoints, and charging spots are digitally mapped for your facility.

03

System Setup

The drone units and docking stations are deployed on-site. No major hardware changes needed.

04

Trial Runs & Calibration

Test flights ensure accurate navigation, scan quality, and dashboard syncing.

05

Go Operational

Your drone inventory solution is live—flying, scanning, and uploading autonomously.

Let us design a solution that fits your facility